FLEXIBILITY

FLEXIBILITY

Today market realities have led to the situation that in majority of cases offering a standard product does not meet Customers’ all needs. Coming across to our partners’ expectation we offer individual approach to every inquiry. This is the reason why fully modified products have been implemented to our offer.

How we do it?

On inquiry reception, our Technical Department selects the equipment which is the closest to Customer’s needs, prepares the model of new solution, tests its accordance to assumed parameters and in case of discrepancies, modifies the project and its technical documentation.

OPENNESS

OPENNESS

OPENNESS

Longstanding knowledge and experience in ventilation solutions, constant investments in development of design and testing possibilities give us potential for new solutions progression. Development of product portfolio often takes place as a result of market demand.

How we do it?

Our contacts in HVAC companies often result in inquiries from Customers in need of help in very untypical solutions. After thorough analysis of our design, construction and testing abilities we can offer a completely new solution, which later successfully is offered on the market.

OPTIMIZATION

OPTIMIZATION

OPTIMIZATION

In the time when the world is constantly changing, when technology is running forward very fast, together with the needs of the market, in order to build competitive advantage, we have to offer more and more efficient and optimized solutions. As a Company with longstanding experience, we hire a high-qualified staff of engineers and designers who constantly work on increasing of our products effectiveness.

Cooperation with Polish Academic Centres such as Cracow, Łódź and Gdańsk Universities of Technology, experience exchange with ventilation companies and investing into development and training of our staff help us to support these activities. This way we turn the newest ideas of Polish academics and branch specialists into modern and more effective product.

QUICKNESS

QUICKNESS

QUICKNESS

Today market environment can be defined in many different ways, but all the definitions have common thread – time. The Customer expects quick selection of equipment, quick price calculation and in the end – quick production and delivery to required destination.

How do we adjust to these requirements?

Using of modern selection program and exploiting the knowledge and experience of our engineers, we are able to select and evaluate each solution. Making use of specialized software and the knowledge of our designers, allows us to prepare technical documentation with all changes implemented in a very quick time.

Our orderly workshop equipped with modern machines guarantees completion of an order within one of the shortest delivery times on the market. We cooperate with transport companies who deliver entrusted cargoes within 48 h at any destination in Poland, and as fast as possible to any place in the world.

SUPPORT

SUPPORT

SUPPORT

In our Company selling of the equipment is not the end, but rather it is the beginning of cooperation with Customer. We offer support in launching of installation in Poland as well as abroad, maintenance reviews within and after guarantee, instant response to problems and quick access to spare parts. If needed, we prolong guarantee period.

Why do we do it?

We treat these activities as a mission – as a brand of Mawent we do exist on the market for over 60 years. That is why we are concerned about keeping our name to be identified with solidarity and reliable products.

AND MORE...

AND MORE...

AND MORE...

It is very common that the problems with installation appear long time after equipment’s launch. They arise from not only defective construction or wrong operation, but also from changing of environmental and administrative requirements. Trying to meet our partners’ expectations we offer a number of services related to testing, maintenance and repair of ventilation equipment, of our production as well as of our competitors.

How do we do it?

As one of the few companies in the branch we do possess efficient technical service which reviews, repairs and replaces components in a quick and effective way. Additionally, we are able to measure the most important parameters, design appropriate documentation and also suggest improving solutions according to new requirements.

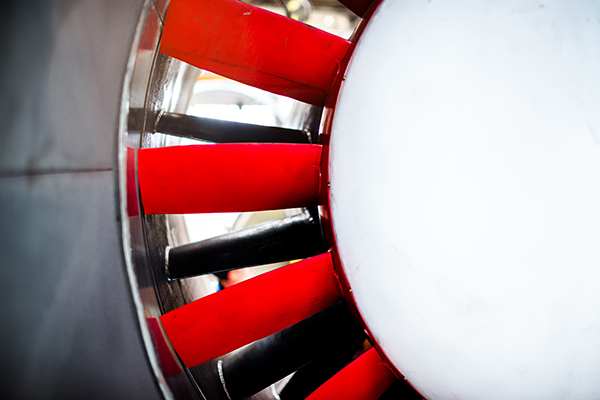

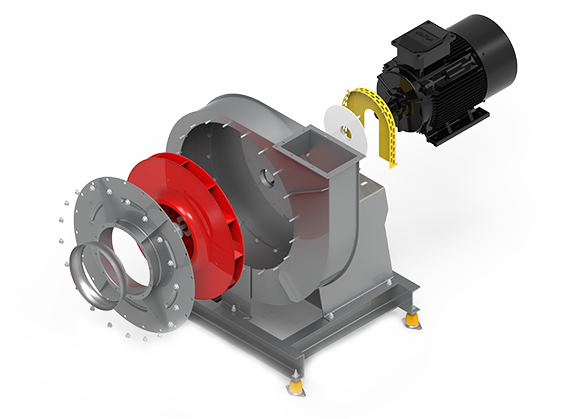

Fan skid WOL was designed in cooperation with Gdańsk Ship Design and Research Centre. It is intended to work in closed aerodynamic tunnel with changing turbulences, however it can also successfully work in technological installation as an axial fan.

Fan skid WOL was designed in cooperation with Gdańsk Ship Design and Research Centre. It is intended to work in closed aerodynamic tunnel with changing turbulences, however it can also successfully work in technological installation as an axial fan. APPLICATION

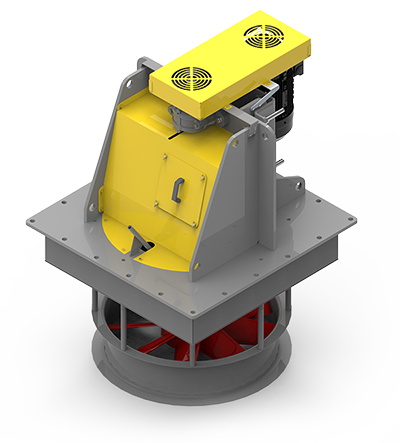

APPLICATION Atmosphere mixers are the fans intended for even distribution of air or nitrogen in closed chambers.

Atmosphere mixers are the fans intended for even distribution of air or nitrogen in closed chambers.