Fan types

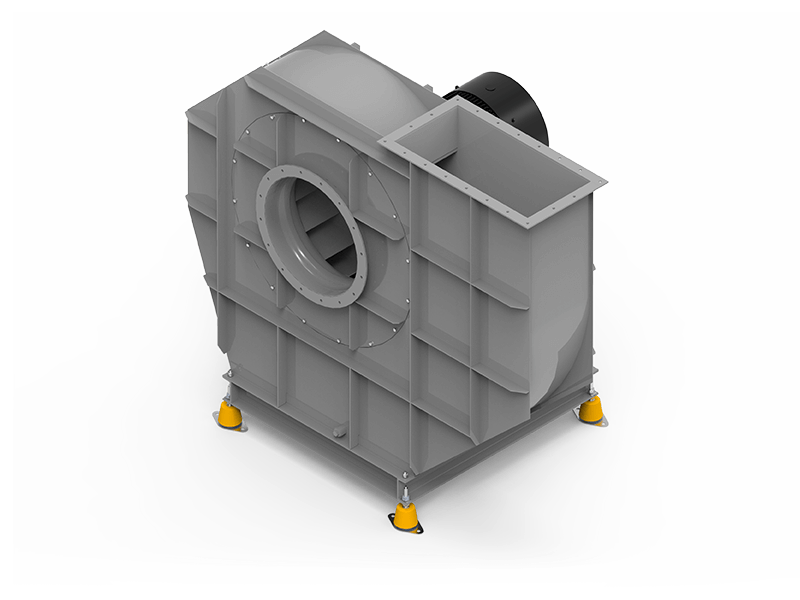

Product description

Application

Centrifugal WPSS fans are intended for pressing of agent with increased level of dust in general ventilation systems and process lines. Allowable dust content must not exceed 3g/m3.

Construction

Main elements of the set such as: impeller, casing, base frame are made of standard steel of ordinary quality. In corrosion and heat-corrosion resistant executions the impeller and casing are made of steel with increased resistance to corrosion. On client’s request other kinds of steel can be used.

ATEX

The explosion-proof fans are meant for operation in potentially explosive areas according to ATEX 94/9/WE directive.

Available executions

- Zones 2 and 1 for gases (3G/2G)

- Zones 22 and 21 for dusts (3D/2D)

Drives

- Direct drive (1) – up to 80°C

- Direct drive-C* (1) – up to 220°C

- Indirect belt drive (2) – up to 250°C

- Indirect coupling drive (4) – up to 350°C

Protection against corrosion

- Standard execution – painting with standard set of paints, C3 class, RAL 5009,

- Heat resistant execution – painting with a set of paints resistant to heat up to 350°C

Options

- Hot deep galvanizing

- Acid treatment

- Passivation

- Glass blasting

- Chemo-resistant painting

- Painting in C4 and C5 classes on Client’s request.

Motor

In standard the fans are driven by three-phase electric motors in IP55 execution, insulation class F, from world-renown producers. Ambient temperature must not exceed 40°C.

Motors for special execution available on Client’s demand.